Product Overview

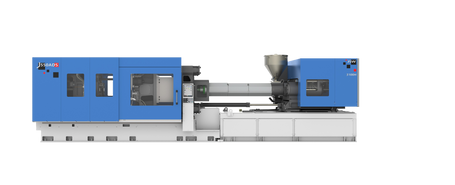

JSW Large-Size J-ADS Injection Molding Machines

The JSW J-ADS Series large-size injection molding machines (J550ADS–J850ADSW) are built for demanding, high-volume manufacturing environments where speed, power, and reliability are critical. Backed by JSW’s decades of engineering excellence, these machines feature high-rigidity clamping units, advanced injection systems, and next-generation smart controls that enhance productivity while reducing cycle times. Designed to handle larger molds with precision and efficiency, the J-ADS large-size series delivers stable, energy-conscious performance and the intelligent integration required for today’s connected, high-output production floors.

View the Large Size JADS Series brochure

View Large Size JADS Specifications

Contact us to learn more at 706-557-8397